In many projects — whether drones, robotics, automation or motorsport — carbon fiber parts are only half the solution. They are often accompanied by precision aluminum components.

That’s why we’ve now added aluminum to our material portfolio. Same platform. Same speed. Same reliability

CNC milled aluminum – a high-quality alternative to laser/water cutting

Unlike laser or water jet cutting, we use CNC milling technology to produce all aluminum parts. This ensures: significantly better edge quality (no melting or burning marks)

higher dimensional accuracy – according to ISO 2768-m tolerances

clear edges and precise holes, also suitable for threading or precision mounting

Which aluminum alloy we use?

All parts are made of 6082 T6 aluminum alloy – strong, easy to machine and very common in engineering applications.

Available in material thicknesses: 3 mm, 4 mm, 5 mm, 6 mm, 8 mm and 10 mm

Fully in-house milling with our own CNC milling machines.

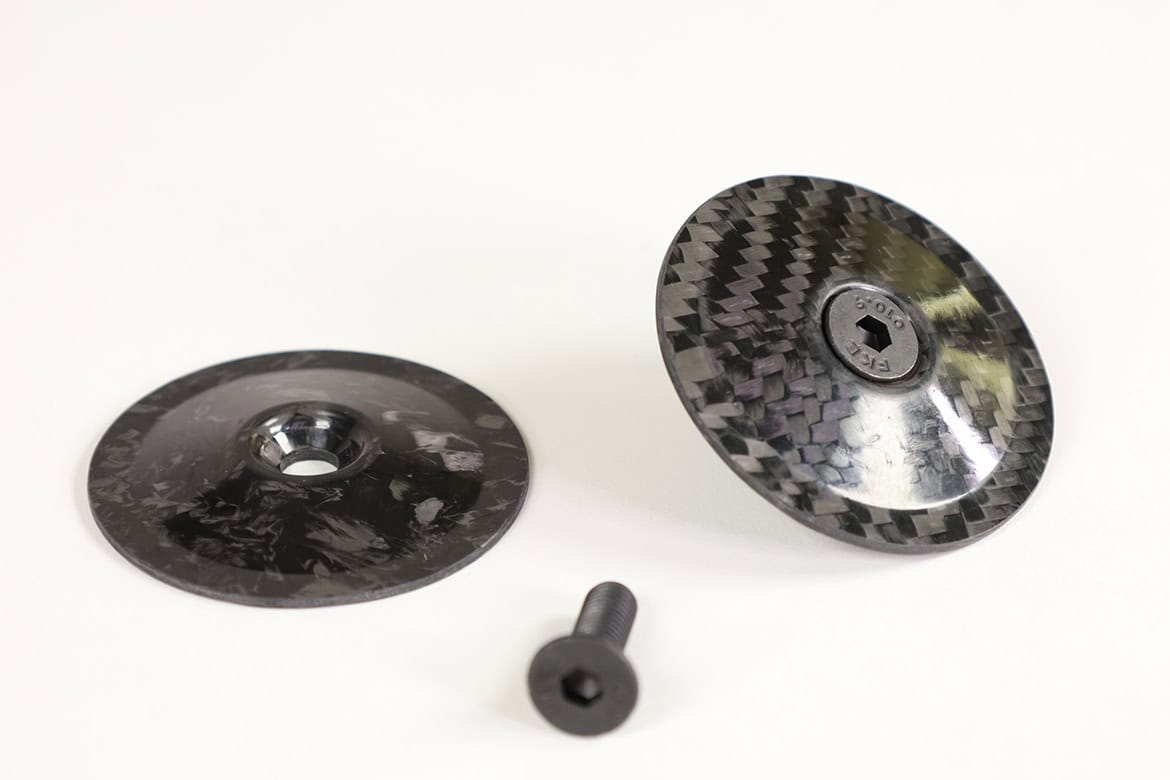

Carbon fiber(CFRP) + aluminum – the perfect combination

Today’s technical projects often require both carbon fiber and aluminum parts in the same structure.

Now you have the opportunity to order both materials from one place.