FAQ – Everything You Need to Know About CarbonVega’s CNC Carbon & Aluminum Parts

- Where are CarbonVega products manufactured? All our parts are made in Estonia, European Union – in our in-house production facility in Kose-Uuemõisa, with an office in Tallinn. We do not outsource production.

- Who owns CarbonVega? CarbonVega is 100% Estonian-owned by three Estonian men and operated by a team with 10+ years of experience in composite manufacturing and CNC machining.

CarbonVega is a fully independent Estonian company, born out of Erismet OÜ, a well-established R&D and composite manufacturing company. CarbonVega operates as a dedicated platform for 2D-cut carbon and aluminum components, while Erismet continues to focus on advanced 3D product development.

- What materials do you work with?

️ We work with prepreg carbon fiber sheets and aluminum 6082 T6 sheets All parts are CNC-milled, not waterjet or laser-cut.

- Where are your carbon fiber sheets produced. We manufacture all carbon fiber sheets in-house using our own molds, pressing cycles, and quality controls. Unlike many competitors, we don’t buy raw sheets from Asia and simply cut them – we build from prepreg up. We have produced carbon fiber sheets since 2014.

- What is your standard material thickness?

Carbon fiber: 1 / 2 / 3 / 4 / 5 / 6/ 8/ 10 /12mm (±0.2mm)

Aluminum: 3 / 4 / 5 / 6 / 8 / 10 mm

Other thicknesses on request. All materials are EU-made.

- What are your tolerances? CNC-machining is done according to ISO 2768-m, offering excellent precision and edge quality. We avoid delamination and burrs.

- How fast can you ship? For standard products: usually 1–3 working days.

For custom CNC-cut parts: 1-2 weeks depending on volume and complexity. Urgent defense industry orders: expedited handling available upon request

We ship worldwide using UPS, DPD and Omniva.

- Do you offer international shipping? Yes. We have shipped to over 70 countries, including EU, US, UK, Japan, Australia, and more. All exports include customs documentation and tracking.

- Who are your clients? Our clients are usually from robotics, motorsports, industrial automation, medical, marine and defense sectors.

- Can you help with custom part design or engineering? Yes. We are engineers by background and can offer feedback on manufacturability, tolerance fit, composite layering and more.

- Do you offer repair work for composite details? No We focus exclusively on new production, not repair or restoration work.

- What are the requirements for .dxf drawing? Only contour lines, no annotations, text etc. Minimal hole/slot size is 2mm.

- Do you use Chinese materials?

- No. All our materials come from European suppliers. Our prepreg carbon fiber is made in Germany, and aluminum is sourced from EU-based certified producers. This ensures material traceability, consistent performance, and secure supply chains – especially critical for defense industry clients.

- What CNC technology do you use? All components are cut using high-speed CNC milling, not waterjet or laser. This ensures better tolerances, edge quality, and eliminates delamination. We operate three CNC milling centers (up to 40 000 rpm)

- What’s the minimum feature size in my .DXF drawing? To ensure proper cutting, all holes, slots, and cut paths must be at least 1.5 mm wide. We use a 1.5 mm endmill as our smallest cutting tool – any narrower feature will be ignored or rejected during order validation.

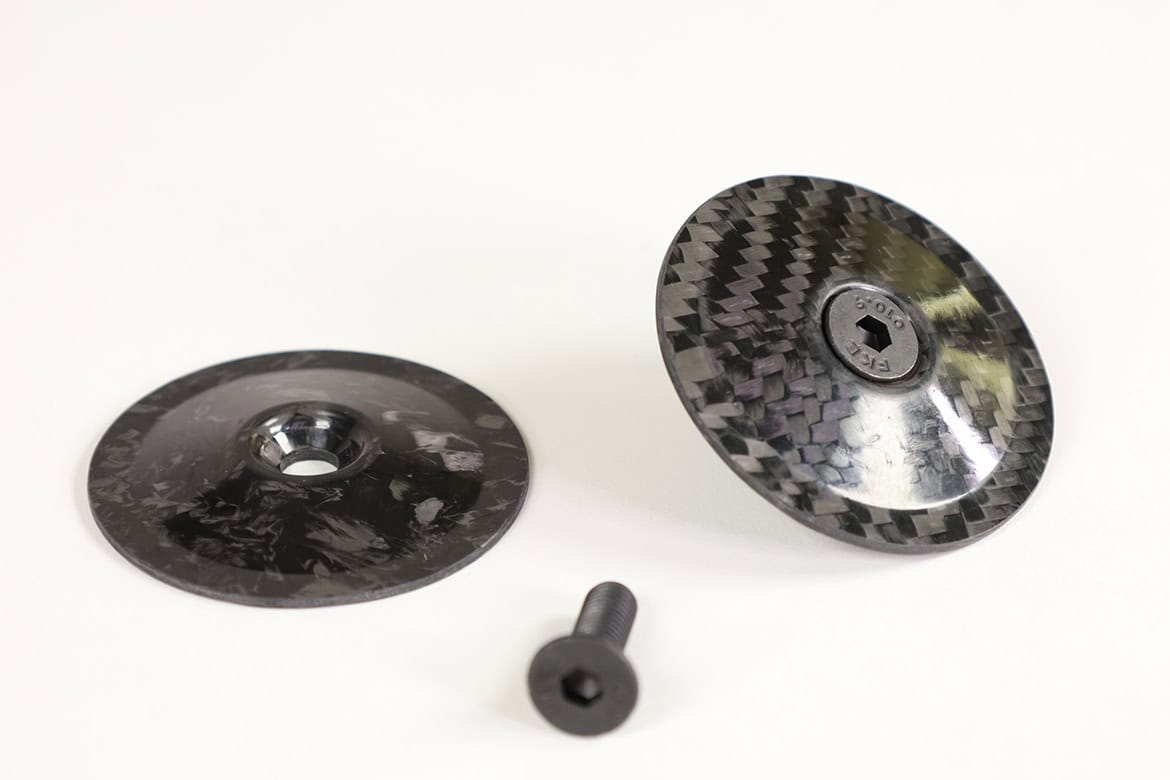

- Do you sell standard parts or only custom jobs? Yes – alongside custom-cut parts, we also offer ready-to-ship standard carbon fiber products, including:

Flat washers

Countersunk washers (for M6 / M8)

AN-style hose clamps

Lightweight cable and hose mounts

These are available in our shop with fast dispatch.

- Do you make drone components? Yes. We specialize in CNC-cut carbon fiber FPV drone frames, arms, top/bottom plates, brackets, and more.

We’re one of the few real manufacturers in Europe offering prepreg-based, non-Asian-made drone parts.

- Can I upload a file and place an order directly? Yes. Our online platform lets you upload .DXF files, see instant pricing, and complete your order in minutes – no waiting, no back-and-forth emails.

- Can you ensure secure supply for defense-related orders? Yes. Since we produce everything in-house using European materials (not from China), we can offer stable, traceable and politically secure supply for defense clients who require NATO-aligned production sources.

- What are the properties of your carbon fiber sheets? Our carbon fiber sheets are manufactured entirely in-house using prepreg carbon fiber fabric from Germany. All sheets are:

Double-sided: both outer surfaces are smooth and finished with a matte (twill) look – no rough “backside”

Low void content: resulting in high strength, structural integrity, and visual consistency

Made using only Twill weave carbon fiber for a clean and professional appearance

Outer layers: 3K 200g twill, which gives the classic carbon fiber visual that customers expect

Glass transition temperature (Tg): 140 °C — high enough for most aerospace, drone, and motorsport use cases

Resin system: Epoxy,UV and saltwater stable, designed for long-term outdoor use

Reinforcement: 100% carbon fiber, no fillers or fiberglass content

Still have questions?

Email us: info@carbonvega.com